Envetec Generations

You can use this widget to input text into the page.

ENVETEC GENERATIONS

Currently, all biohazardous waste is autoclaved, incinerated and mostly landfilled.

This process emits huge amounts of CO2 and other greenhouse gases, uses vast amounts of water and is incredibly damaging to the environment. According to Health Care Without Harm, the healthcare sector alone contributes 4.4% of global emissions, and that footprint is forecast to triple by 2050. Something has to change.

Envetec is that change.

GENERATIONS enables circular economy opportunities for biohazardous waste by simultaneously shredding and disinfecting this material at source

How It Works

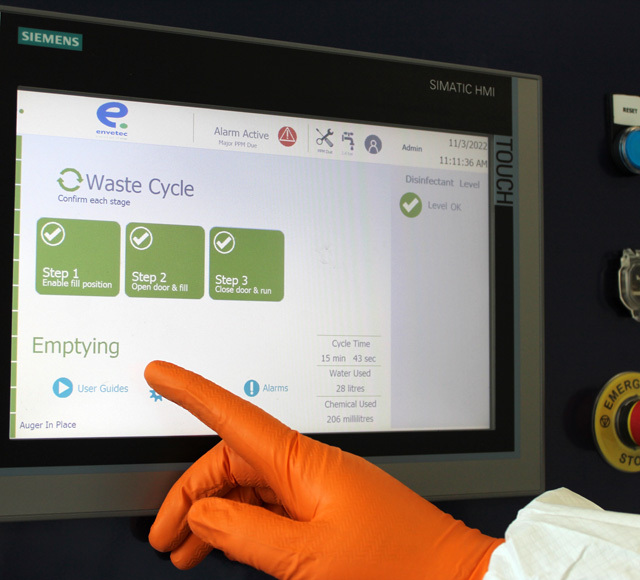

Human Machine Interface

Powered by Siemens Insights Hub our intuitive HMI is the brain of the GENERATIONS technology. The user friendly interface can initiate a treatment cycle in three clicks, detect and communicate issues and capture real time data for remote diagnostics and carbon reporting.

Receiver

The heart of the GENERATIONS unit. The entire treatment process, both shredding and disinfection take place in the receiver. The receiver is dynamic and automatically adjusts position for ease of loading and to release treated material post cycle

Chemical

GENERATIONS utilises an organic, biodegradable chemical to achieve STAATT IV (6log10) inactivation of microbes. Post treatment the chemical breaks down into ethanoic acid and water.

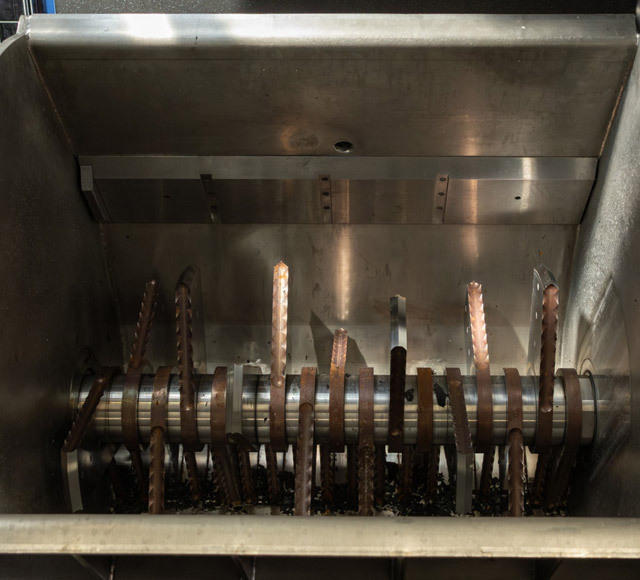

Blades

GENERATIONS robust blade system is designed specifically to shred biohazardous/regulated medical waste. The smart blade system assess resistance of a waste load at the beginning of every cycle to determine the optimal power output required for shredding and ensure that material placed in the receiver is suitable for shredding.

Validation System

This novel validation system validates the efficacy of the GENERATIONS process during live waste processing ensuring the highest level of confidence in the efficacy.

Auger

Post treatment this dewatering auger receives treated material and separates solid from effluent. Pushing treated solid material into a receptacle and sending effluent to the GENERATIONS filtration system.

Neutralisation & Filtration

Depending on material being treated neutralizer may be dosed to ensure a PH that is acceptable for effluent and solid material. PH balanced effluent is sent to the GENERATIONS filtration unit where it is filtered removing any visible solids and microplastics.

Flake

Treated polymer flake dispensed in the receptacle can now be collected and sent to a material recycling facility for separation and pelletisation.